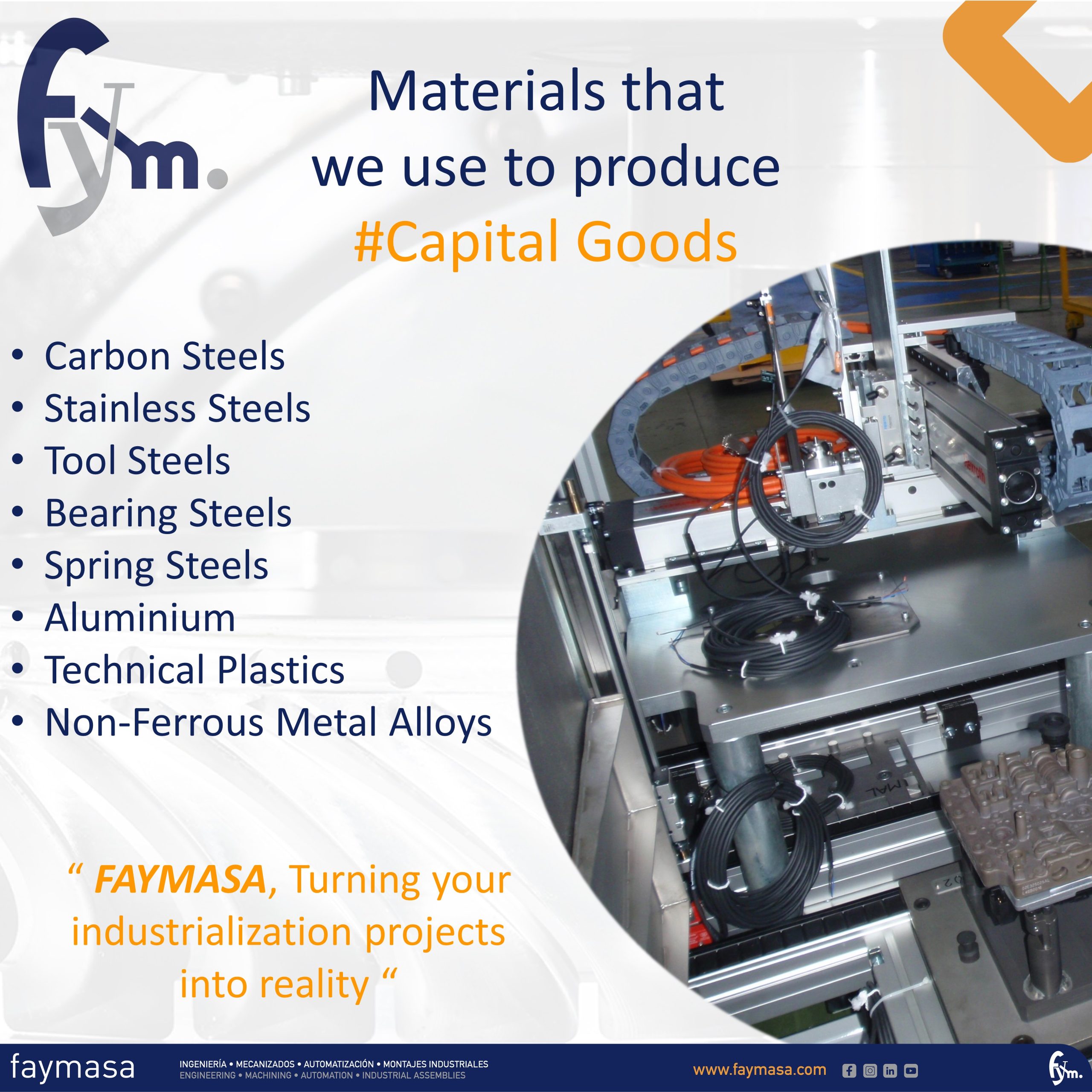

Discover the specific materials that FAYMASA uses when manufacturing capital goods and their most common applications.

From wear resistance to formability, each material has its own characteristics that make it suitable for different applications. Let’s take a look at some of the most commonly used materials and their general applications:

Carbon steels: Known for their resistance and ease of machining, they are widely used in the manufacture of structures.

Stainless Steels: Ideal for applications that require corrosion resistance, such as machinery components in humid or corrosive environments, medical and food equipment.

Tool Steels: Intended for cutting tools, dies and molds that require high resistance to wear and abrasion.

Bearing Steels: Essential in the manufacture of bearings and transmission components that need high strength and durability.

Spring Steels: Used in the manufacture of springs and elastic components that require high resistance and recovery capacity.

Aluminum: Widely used for its lightness, resistance to corrosion and ease of forming.

Technical Plastics: They are mainly used for parts in contact with the final product to avoid aesthetic damage.

Non-Ferrous Metal Alloys: Including alloys of copper, titanium, nickel and other non-ferrous metals for applications that require special properties such as resistance to high temperatures, wear, corrosion or electrical conductivity.

These materials are the backbone of the capital goods industry, ensuring that products are durable, safe and efficient.

Leave A Comment